CNC Lathes and Turning Centers

Our CNC lathes and turning centres continually raise the bar for productivity, performance and reliability… all of which helps to explain their enduring popularity. From DMC compact horizontal single turret 2 axis CNC lathes to DMC twin spindles and heavy duty CNC lathes, there is a machine available to meet your needs. We offer our Machines to clients living in Quebec, Ontario and surrounding areas.

CNC Lathes

Why Choose CNC Lathes and Turning Centers?

CNC lathes and turning centers are integral to many component manufacturing processes.

The machines can produce high-precision, complex parts with intricate features and are widely used to machine aerospace, oil and gas, power generation, motorsport, automotive, medical components to high accuracies and exacting surface finish requirements.

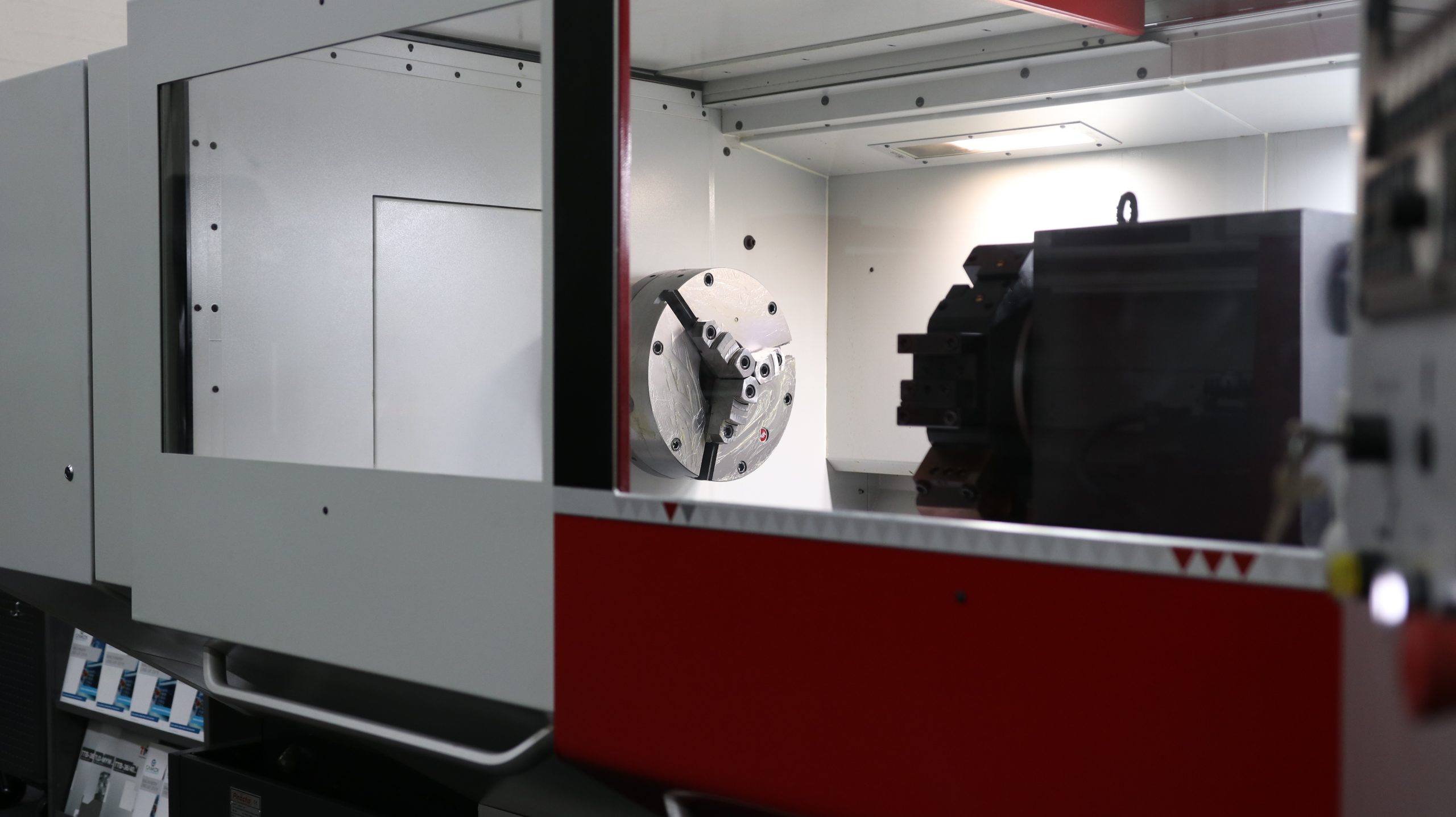

The size of the machine (i.e., chuck and bar diameter size, bed length, distance between centres etc.), dictates the size of component that can be machined. And integrated technologies and additional axes (i.e., driven tooling, sub-spindles, in-process measurement, C-axis and Y-axis etc.), increase lathes’ and turning centres’ capabilities, enabling precision parts to be machined to completion in fewer set ups.

The cost-per-part can also be reduced through automation (i.e. integrating bar feeders, cobots), enabling the machines to run unattended…during the day, overnight and over the weekends too.

Our Products

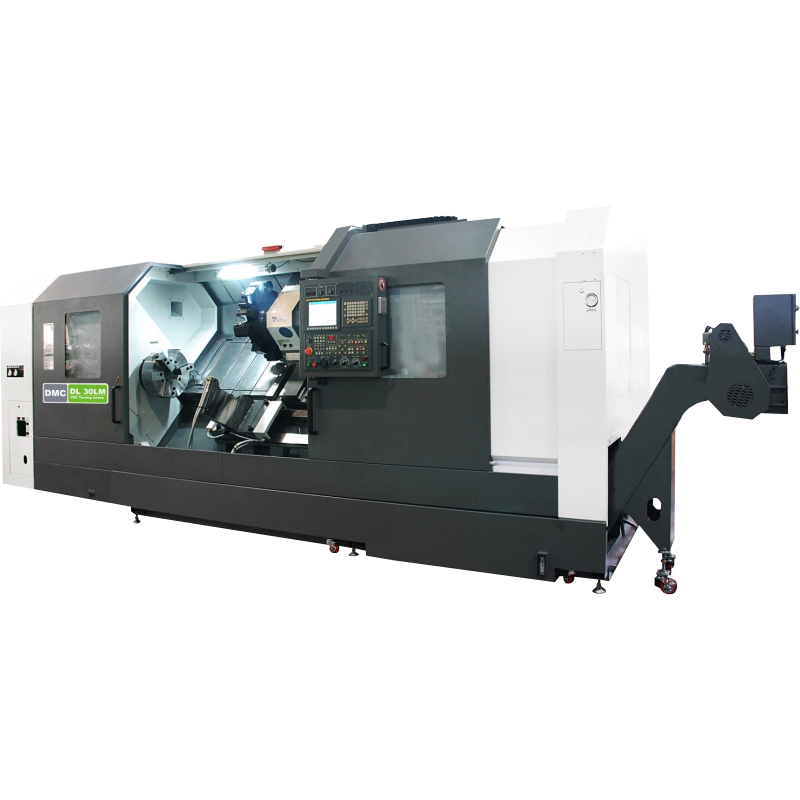

DMC Slant Bed CNC Lathe Series

DMC CNC Vertical Turning Lathe Series

PINACHO CNC Flatbed Lathe Series

PINACHO Manual Lathe Series

Frequently Asked Questions

A CNC turning centre is slightly harder to set up compared to the CNC lathe and you can only operate it via a controller. Yet this choice can perform many more automated tasks at a higher rate than a CNC lathe.